Electrolytic diaphragm bags are central to Bolian’s expertise. We have over 27 years of experience in diaphragm production. This has positioned us as a leader in the electrolytic filtration industry. Our annual production capacity reaches 500,000 square meters, ensuring high-quality solutions that meet the demands of this critical application.

Bolian developed the diaphragm cloth specifically for the electrolytic refining of non-ferrous metals, including copper, nickel, and cobalt. We are the designated supplier for some of the world’s largest nickel and cobalt smelters, as well as the official diaphragm bag supplier for China’s Jinchuan Group. Our advanced materials and expertise ensure optimal performance in these critical refining processes.

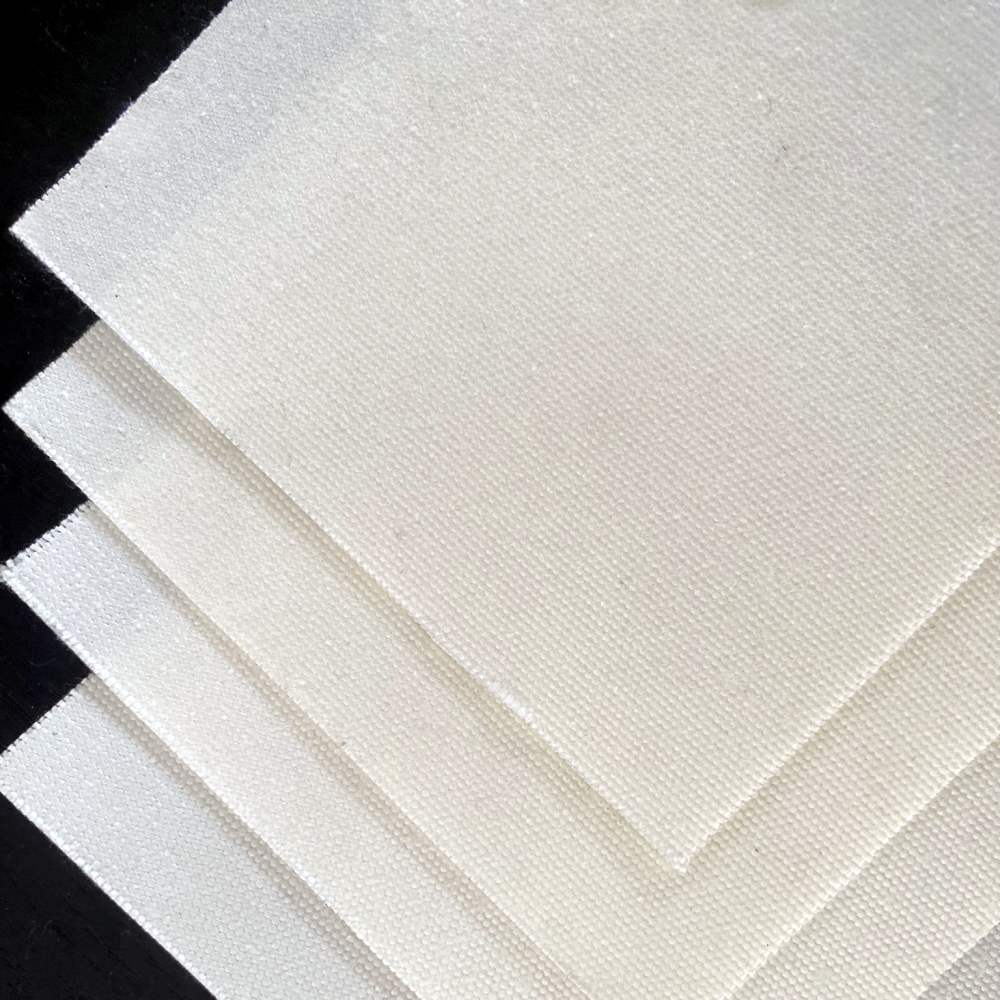

Electrolytic Diaphragm Cloth Features:

- Consistent High Quality: In the production of electrolytic diaphragm bags, full monitoring is used to monitor water permeability and resistivity. On average, the fabric density, weight, water permeability and resistivity are measured every 20 バッグ. In addition, we have the patent for independently developing this product.The diaphragm cloth ensures stable water permeability, offers a service life of up to three months, saves energy, and reduces production costs.

- Stable water permeability and electrolyte level deviation can be achieved in strict accordance with European testing standards;

- The service life can reach more than three months, which increases the service life of the diaphragm bag and improves the quality of nickel plate;

- On the premise of electrolyte level difference, the resistivity of the diaphragm bag is reduced to the lowest point, which saves energy and greatly reduces the cost of producing electrolytic nickel;

- Bolian divides electrolytic diaphragm cloth into various types, including general-purpose, low water permeability, high water permeability, low resistivity, and corrosion-resistant, to suit different working conditions.

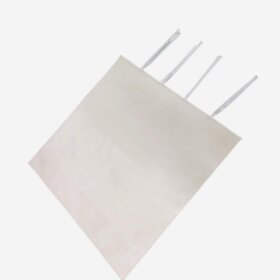

Electrolytic Diaphragm Bags Applications:

Electrolysis diaphragm bags, including anode and cathode bags, are used in non-ferrous metal electrolysis and electrowinning refining. They serve mining industries under both vulcanization and chlorination systems.

- nickel smelting;

- electrolytic nickel;

- nickel electrowinning;

- electrolytic copper/ refinery;

- High copper refinery, etc.

We can also optimize the design of new fabrics based on customers’ specific electrolysis processes. Additionally, we provide guidance to ensure reliable technical support for our customers.

ボリアンフィルタークロス

ボリアンフィルタークロス