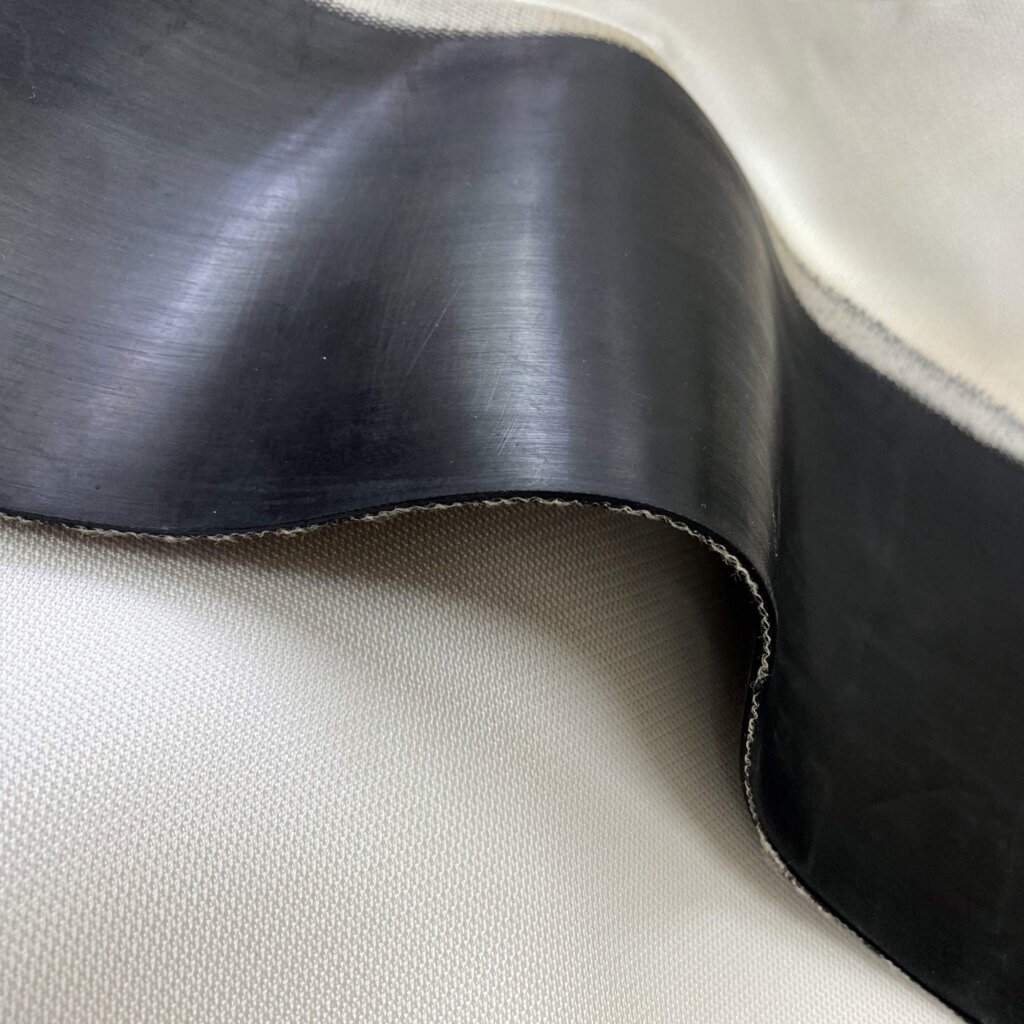

High-capacity フィルタープレスクロス is often used in traditional horizontal filter presses. Bolian developed this product especially for high-capacity filter presses, also known as vulcanized filter press cloth or glue-hanging filter cloth. High-capacity filter press is a new type of horizontal filter press, with characteristics of low filter cake moisture content, high degree of automation and good washing performance. The equipment relies on the anti wind to remove water, which has high demands on the sealing of the filter chamber. Therefore, the filter cloth of the equipment must undergo special sealing treatment.

Why choose vulcanized filter cloth?

Vulcanized filter cloth for nickel concentrate

- The rubber is tightly bound to the filter cloth through a specialvulcanization process, ensuring a good sealing performance. It can prevents air leakage when the filter machine is blowing in reverse;

- Natural rubber is a superior material to synthetic rubber due tosoftness, adhesion, environmental friendliness, and vulcanization strength. It is not easy to debond, bulge, or other issues, but it can withstand high pressure.

- Under the same conditions, the vulcanized filter cloth has better sealing performance and higher blowing efficiency, so the moisture content can be less than 15%.

- Under continuous operation, the average service life of vulcanized filter cloth is 45-60 days, which is 30% -50% longer than that of the ordinary filter cloth, greatly improving the working efficiency of the filter machine and reducing

Application

Suitable for copper concentrate, nickel concentrate, gold mine tailings, etc.

Vulcanized filter cloth is widely used in large nickel concentrate, China Gold Mining, China Zijin Mining, etc.

ボリアンフィルタークロス

ボリアンフィルタークロス