PPS Fabric for Hydrogen Energy

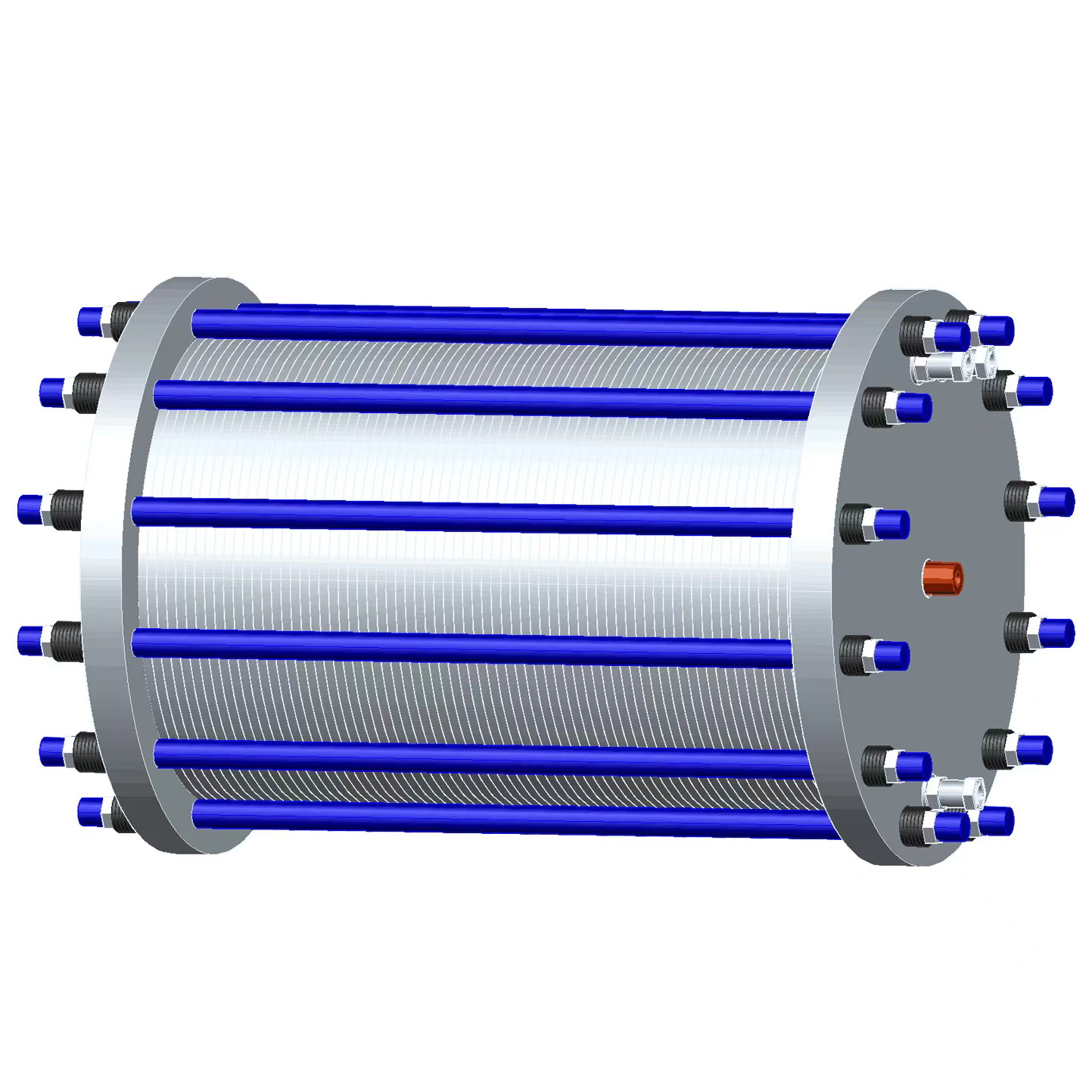

The PPS diaphragm cloth project is based on domestic and international hydrogen energy production processes, and the result can be applied to the electrolysis of hydrogen energy. We offer an extensive product range that can be tailored to suit the specific requirements of on-site working conditions. We have extensive experience in research and development, as well as in production, allowing us to meet the requirements of the electrolysis process.

Durability and Performance of PPS Fabric in Hydrogen Production

PPS (polyphenylene sulfide) fabrics are widely used as diaphragm materials for electrolyzers in hydrogen production. This is due to their excellent chemical stability, heat resistance, and mechanical strength. PPS fabrics can withstand the high temperatures generated during the hydrogen production process. They also endure strong acidic environments. At the same time, they maintain good electrical insulation properties. Their chemical stability ensures the safety and efficiency of the electrolysis process.

Impact of Diaphragm Cloth Characteristics on Hydrogen Production

Factors such as the thickness, porosity, and pore size distribution of the diaphragm affect the performance during hydrogen production. An appropriate pore structure is essential for ensuring the rapid transport of ions in the electrolyte, while simultaneously reducing gas permeation and maintaining the stable operation of the electrolysis cell.

Precision Control in Diaphragm Cloth Manufacturing for Optimal Performance

Therefore, it is crucial to exercise precise control over the manufacturing process for the diaphragm. This control ensures the desired pore structure and physical properties are achieved. By doing so, we can optimize the hydrogen production process. This will also enhance the performance of the diaphragm fabric in hydrogen production applications.

볼리안 필터 천

볼리안 필터 천